The construction industry in India is facing numerous challenges that are impacting its sustainability. The depletion of natural sand as a resource is a significant concern, with predictions suggesting that it may run out by 2050. Additionally, the sector is grappling with rising carbon dioxide emissions, particularly from the manufacturing of cement and fired clay bricks. Another pressing issue is the increasing amount of construction and demolition (C&D) waste, with approximately 150 million tons being generated annually in India, and only a mere 1% of that waste being recycled.

To address these challenges, researchers at the Center for Sustainable Technologies (CST) at the Indian Institute of Science (IISc) are exploring innovative solutions. One such approach involves storing carbon dioxide from industrial flue gas in excavated soil and C&D waste, which can then be used to partially replace natural sand in construction materials. This not only helps reduce the environmental impact of construction but also enhances the engineering properties of the materials, making them more suitable for construction purposes.

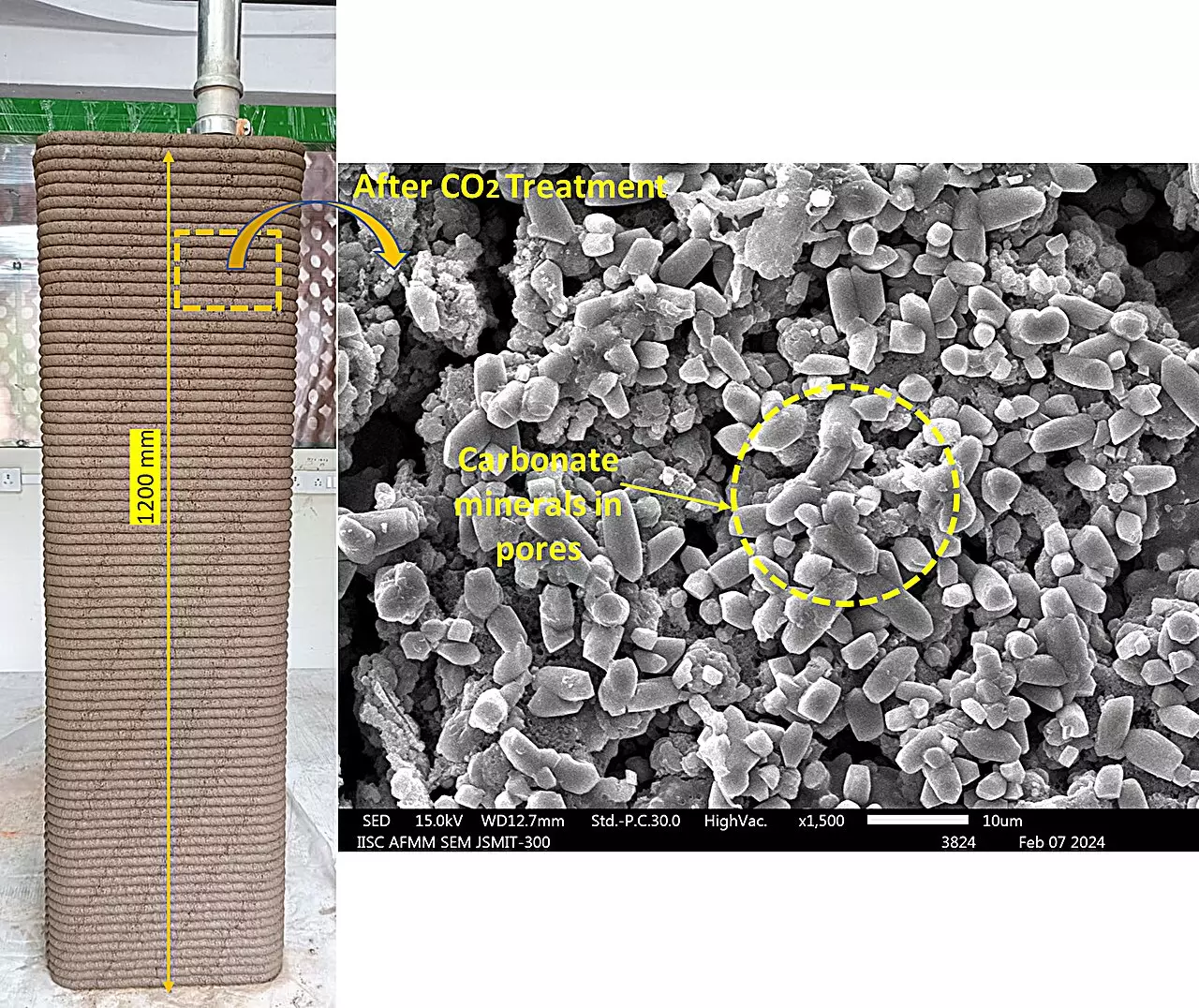

Studies conducted by the CST team have shown promising results. By replacing natural sand with carbon dioxide-treated C&D waste in mortar and curing it in a CO2-rich environment, the development of the material’s engineering properties can be accelerated, leading to an increase in compressive strength by 20-22%. Additionally, injecting carbon dioxide gas into clayey soil has shown improvements in stabilization, reduction of pore volume and lime reactivity, and enhancement of bulk engineering performance.

The team at CST has also looked into the sequestration of carbon dioxide in excavated soil to develop cement-lime-soil materials, which can replace fine aggregates in mortar. This process leads to the formation of calcium carbonates crystals, densification of interfacial zones, and improved compressive strength. The exposure of these materials to carbon dioxide significantly reduces curing time and enhances early-age strength, making them suitable for construction applications.

Moving forward, the research team plans to further study the effects of industrial and simulated flue gas on the properties of these innovative materials. Understanding how gases like carbon dioxide, sulfur dioxide, and nitrogen oxide impact carbon-capturing potential and engineering properties will be crucial for their application in the construction industry. The team is also in discussions with major construction companies to implement these sustainable solutions in their manufacturing processes.

The innovative research being conducted at CST offers promising solutions to the challenges faced by the construction sector in India. By exploring ways to utilize carbon dioxide and repurpose C&D waste, the team is not only addressing environmental concerns but also enhancing the performance of construction materials. With a focus on sustainability and collaboration with industry partners, these efforts are paving the way for a more environmentally friendly and efficient construction sector in India.

Leave a Reply