In our increasingly electrified world, the role of small electric motors cannot be overstated. Ubiquitous in everyday appliances, tools, computers, and modern automotive systems, these motors serve fundamental purposes, powering everything from pumps and fans to lighting systems. While each individual motor appears to consume negligible energy, when considered collectively across various devices, their contribution to overall energy use is substantial. Developing more efficient small electric motors can lead to significant energy savings and operational efficiencies. The research team led by Annette Mütze at the Graz University of Technology (TU Graz) has taken strides in harnessing this potential.

At the heart of Mütze’s research is an innovative approach to designing and controlling brushless integrated drives. Unlike traditional motors, which often operate with significant energy waste and noise, these new systems have been engineered to consume less energy while producing less sound. They achieve this through advanced design methodologies, improved control technologies, and the integration of modern manufacturing processes.

One notable advancement involves the design of claw pole motors, which, while primarily known for their applications in larger lighting systems, have now been adapted for smaller motor uses. The team’s iterative modifications, such as skewing and slotting the motor claws, have yielded impressive results in reducing cogging torque—the unwanted resistance felt when the motor rotates. By lessening this torque without incurring extra costs, the motors not only achieve smoother rotation but also experience a remarkable 70% decrease in noise, enhancing both performance and user experience.

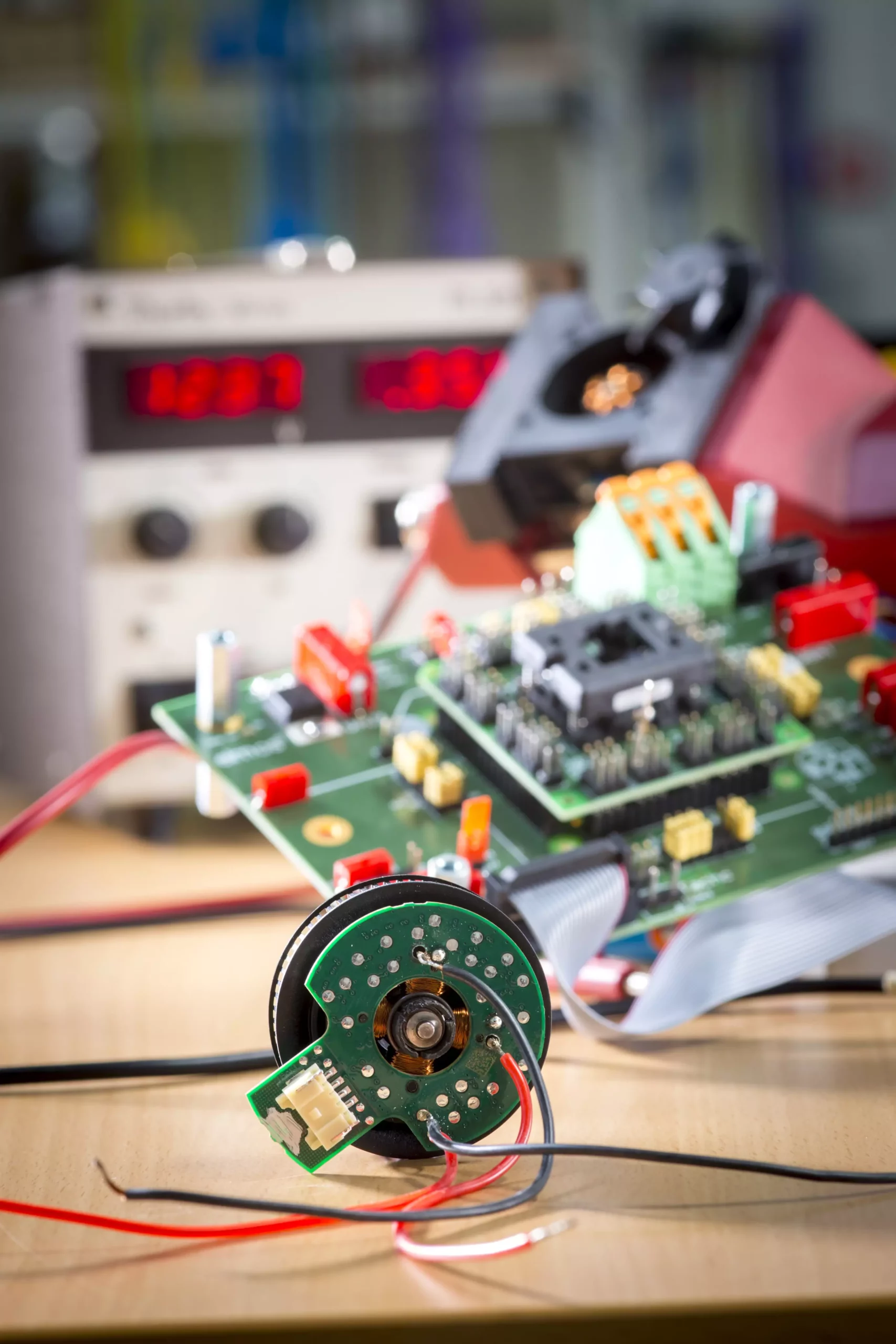

A critical component of the innovation in brushless motors lies in the optimization of current regulation. Traditionally, pulse width modulation (PWM) has been the go-to method for controlling the current supply to fans or pumps. This technique, while effective, often demands a high frequency of switching operations that can lead to increased energy loss due to switching actions. Mütze’s team has pivoted from this conventional approach, advocating for a simpler on-off switching mechanism that only activates per desired rectangular waveform.

This fundamental alteration allows for a marked decrease in the energy lost during the switching process, particularly at lower currents. The enhanced efficiency translates into a broader scope for application in scenarios where energy conservation is paramount. Moreover, a reduction in the number of necessary capacitors on the circuit boards—cutting them down to half—not only curtails production costs but also optimizes the motor’s operation.

The introduction of printed circuit board (PCB) motors with embedded ferrite cores represents another groundbreaking step in brushless motor technology. In this design paradigm, the windings used to generate magnetic fields are integrated directly onto circuit boards, fostering greater production automation. This development not only streamlines the manufacturing process but also enhances performance through innovative magnetic flux guidance.

By equipping these circuit boards with 3D-printed ferrite cores, the team has succeeded in improving the efficiency of the magnetic field interactions within the motor. This innovation lays the groundwork for utilizing more cost-effective magnets, fortifying the overall economics of producing high-efficiency motors. The combined effect of these advancements suggests a substantial leap toward more sustainable motor solutions that can be widely adopted across industries.

The Future of Efficient Electric Drives

The research spearheaded by Mütze and her team at TU Graz emphasizes the necessity for continual innovation in the realm of small electric motors. The advancements in design, control methods, and manufacturing techniques mark a significant move toward enhancing energy efficiency and reducing operational noise. By harnessing the collective impact of these innovations, we can look forward to a future where household appliances and vehicles operate more quietly, consume less energy, and contribute to a more sustainable environment.

This endeavor not only advocates for operational advancements in motor technology but also aligns closely with global efforts aimed at energy conservation and environmental preservation. As we embrace these innovations, we step toward a more energy-efficient and quieter tomorrow.

Leave a Reply