The battery industry is facing a pivotal moment as sustainability becomes a central focus amid rising environmental concerns. Conventional lithium-ion batteries, which have been staples in various applications, often rely on harmful fluorinated compounds. This reliance presents significant challenges, particularly regarding environmental impact and regulatory compliance. With the European Union gearing up to impose stricter regulations on per-and polyfluoroalkyl substances (PFAS) by 2026, there is a pressing need for alternative solutions that not only meet performance standards but also align with eco-friendly principles.

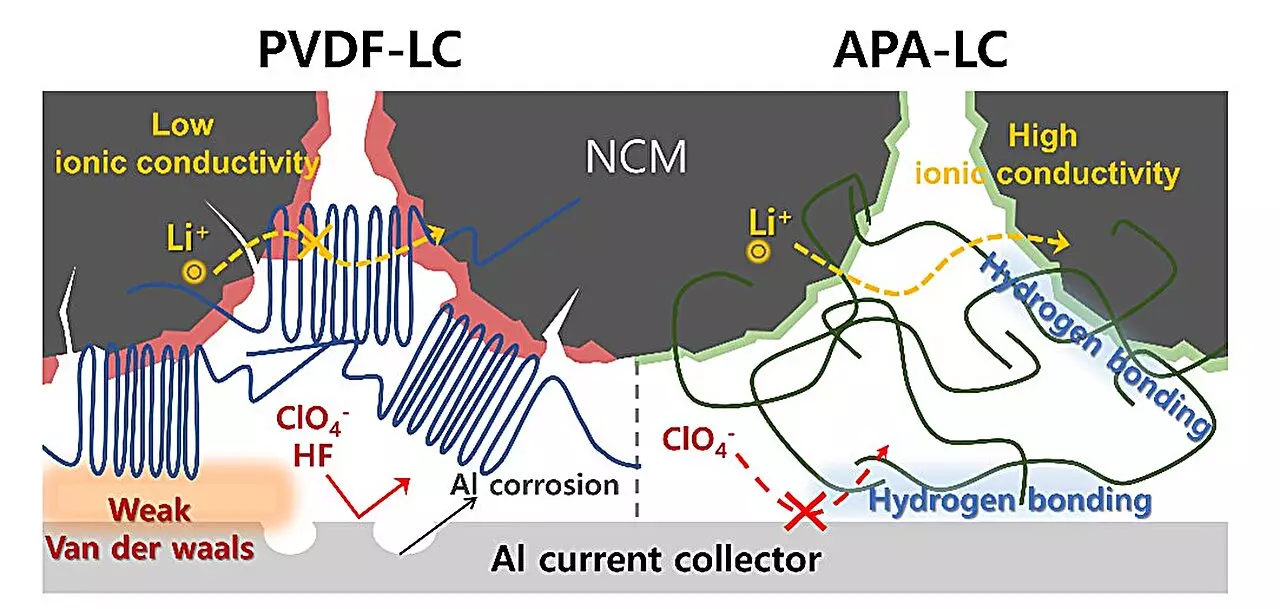

Traditional lithium batteries predominantly use polyvinylidene fluoride (PVDF) as a binder and lithium hexafluorophosphate (LiPF6) as an electrolyte. These compounds, while effective, pose serious environmental risks. The degradation of PVDF leads to the release of toxic hydrogen fluoride (HF), significantly diminishing the longevity and performance of the batteries. Additionally, the non-biodegradable nature of PVDF and the toxic byproducts associated with its use contribute to the growing call for sustainable materials in the battery manufacturing process. This scenario intensifies concerns as the industry grapples with the need for a transition to safer alternatives.

A recent study published in the Chemical Engineering Journal sees researchers from POSTECH and Hansol Chemical stepping into the fray with groundbreaking advancements. They have successfully developed a fluorine-free binder and electrolyte system that aligns with both performance needs and environmental considerations. The newly conceptualized “APA-LC” system utilizes lithium perchlorate (LiClO4) as the electrolyte and a non-fluorinated aromatic polyamide (APA) as the binder, entirely removing the fluorinated components that have long been the industry standard.

This innovative combination not only addresses the acute need for compliance with upcoming regulations but also enhances battery performance. The APA binder provides superior adhesion between the active materials of the cathode and the current collector, critically reducing the risk of corrosion and thus extending battery life. Simultaneously, the LiClO4 electrolyte, augmented with lithium chloride (LiCl) and lithium oxide (Li2O), optimizes ion transport, facilitating quicker lithium movement and improved overall performance.

The performance metrics of the APA-LC system speak volumes about its efficacy. In tests, it exhibited remarkable oxidation stability, outstripping the traditional PVDF-LP setup. With a 20% improvement in capacity retention over 200 cycles during rapid charge and discharge processes, the new system shows significant promise for real-world applications. The development of a high-capacity 1.5 Ah pouch cell using the APA-LC setup demonstrated not only excellent discharge capability but also robust performance during fast-charging tests, firmly establishing a benchmark for competitive, eco-friendly battery solutions.

The contributions of Professor Soojin Park of POSTECH and Manager Young-Ho Yoon of Hansol Chemical underscore a proactive vision for the battery sector’s shift towards sustainability. Their remarks highlight a commitment not only to advancing technology but also to ensuring that the impact on the environment is minimal. As the global market for cathode materials is projected to grow significantly, the APA-LC system positions these researchers at the forefront of transformative developments in the battery arena.

Moreover, this research has broader implications for the energy landscape. By pioneering a non-fluorinated battery system that meets future regulatory standards, it sets a precedent for other industries looking to innovate responsibly. The transition to greener technologies is not merely a response to legislation but a vital component of ensuring a sustainable future.

As we look to the future of energy storage solutions, the advancements created by POSTECH and Hansol Chemical present a favorable outlook. The unveiling of a fluorine-free battery technology symbolizes not just an innovation in material science but an essential step towards more environmentally-friendly practices. As the battery industry navigates its complexities, the priorities must shift to embrace sustainable methods to solidify its role in a greener world. This commitment to eco-friendly solutions will undoubtedly shape the evolution of battery technology in the years to come.

Leave a Reply