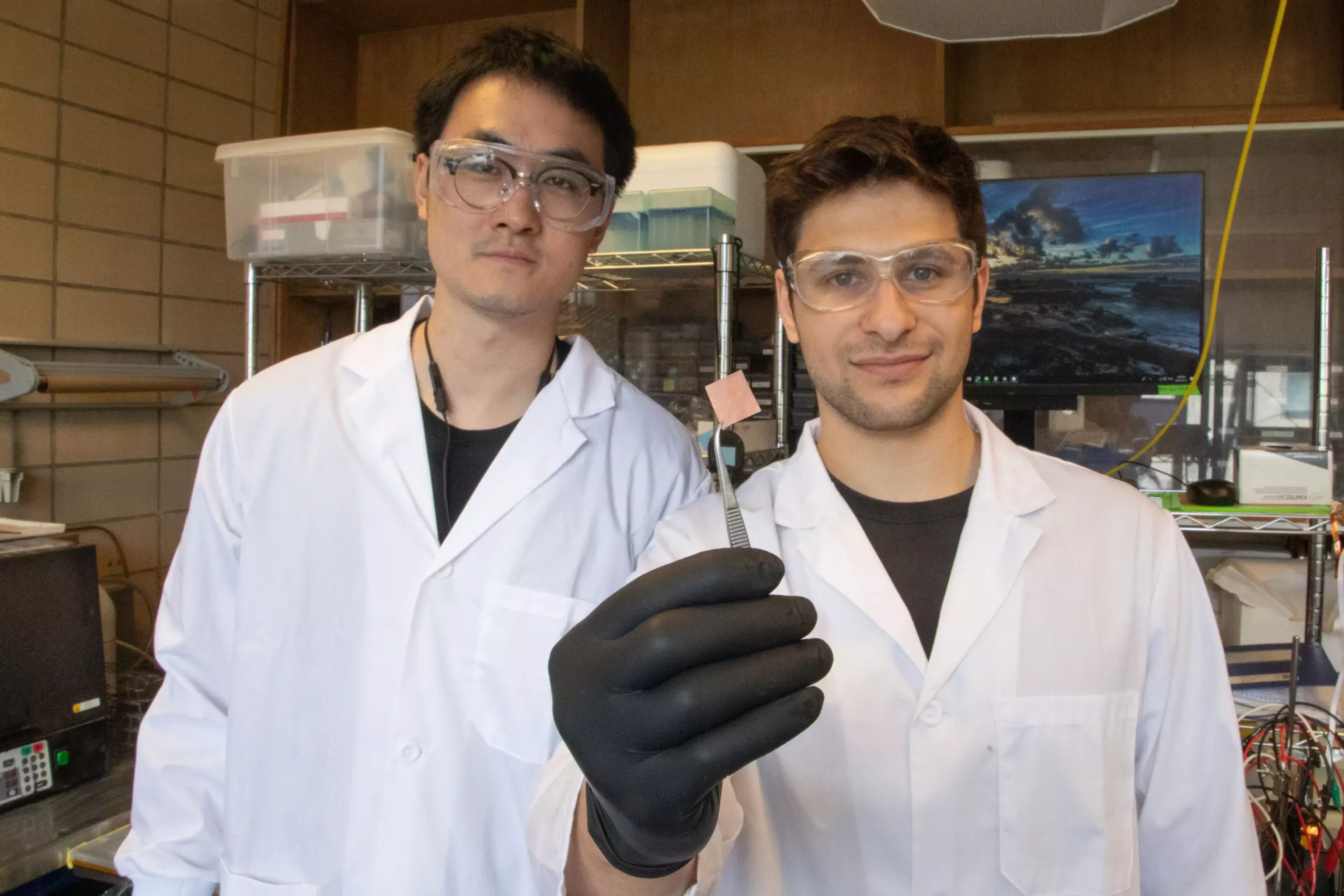

Researchers at the University of Toronto Engineering have developed a new catalyst that shows promise in efficiently converting captured carbon into valuable products despite the presence of contaminants that typically degrade performance. This breakthrough could revolutionize carbon capture and storage methods, particularly in industries like steel and cement manufacturing that are harder to decarbonize. The catalyst described in a paper published in Nature Energy offers a cost-effective solution for upgrading carbon waste streams.

Efficient Conversion Process

The team led by Professor David Sinton utilizes electrolyzers to convert CO2 and electricity into carbon-based molecules such as ethylene and ethanol. These products can be utilized as fuels or raw materials for the production of various everyday items. The conversion reaction occurs within the electrolyzer, where CO2 gas, electrons, and a water-based liquid electrolyte interact on a solid catalyst surface. While copper is a common catalyst material, variations containing additional metals or organic compounds can enhance performance by accelerating the reaction and minimizing the formation of unwanted byproducts that reduce efficiency.

Challenges of Impurities

Most existing catalyst designs are optimized for pure CO2 feeds, rendering them susceptible to performance degradation when exposed to impurities like sulfur oxides (SO2). These contaminants bind to the catalyst surface, reducing the available reaction sites and causing the generation of undesirable chemicals. Sulfur oxides can rapidly decrease catalyst efficiency, posing a significant challenge to carbon conversion processes. While methods exist to eliminate impurities from CO2-rich exhaust gases before entering the electrolyzer, these techniques are time-consuming, energy-intensive, and costly.

To address the issue of SO2 poisoning, the research team modified a standard copper-based catalyst by adding two key components. A layer of polyteterafluoroethylene, commonly known as Teflon, was introduced to alter the surface chemistry and prevent SO2 reactions. Additionally, a layer of Nafion, an electrically-conductive polymer, was applied to create a barrier that inhibits SO2 access to the catalyst surface. This novel catalyst configuration exhibited resilience to sulfur oxides, even when subjected to a mix of CO2 and SO2 mimicking industrial waste stream conditions.

The newly developed catalyst achieved a Faraday efficiency of 50%, demonstrating consistent performance over 150 hours under challenging conditions. While some catalysts may initially offer higher efficiencies, they often rapidly deteriorate in the presence of contaminants like SO2. The versatility of this approach, which does not alter the catalyst composition, indicates its potential for widespread application. Research teams with established high-performing catalysts can leverage similar coatings to enhance resistance to sulfur oxide poisoning.

Although sulfur oxides present a significant hurdle in waste streams, the research team aims to expand their focus to encompass a broader range of chemical contaminants. By addressing challenges such as nitrogen oxides and oxygen, the catalyst’s effectiveness can be further validated across various industrial settings. The success of combating sulfur oxide poisoning opens doors to exploring solutions for a comprehensive set of impurities, marking a significant advancement in carbon capture and utilization technologies.

The development of a resilient catalyst capable of efficiently converting captured carbon in the presence of challenging impurities represents a pivotal advancement in the realm of carbon capture and utilization. The innovative approach showcased by the University of Toronto Engineering team provides a sustainable solution for upgrading carbon waste streams and contributes to the ongoing efforts towards achieving a low-carbon economy. As industries strive to reduce their environmental footprint, breakthrough catalyst technologies like the one described in this study offer a promising pathway towards sustainable carbon management.

Leave a Reply