The emergence of new technologies aimed at recycling rare-earth elements (REEs) is rapidly gaining momentum, especially as the global push for sustainability intensifies. Researchers from Kyoto University have recently unveiled a revolutionary process, referred to as the selective extraction-evaporation-electrolysis (SEEE) method, designed to enhance the recycling of REEs from end-of-life permanent magnets. With this development, the researchers are not just addressing the pressing issues associated with resource scarcity, but also paving the way toward a greener, more sustainable future.

This study is particularly timely as the world witnesses an exponential rise in the demand for REEs, especially neodymium (Nd) and dysprosium (Dy). These elements are vital for manufacturing high-performance magnets that are crucial components in technologies powering electric vehicles (EVs) and renewable energy sources such as wind turbines. As industries pivot towards more eco-friendly practices, the necessity for effective recycling methods has become paramount.

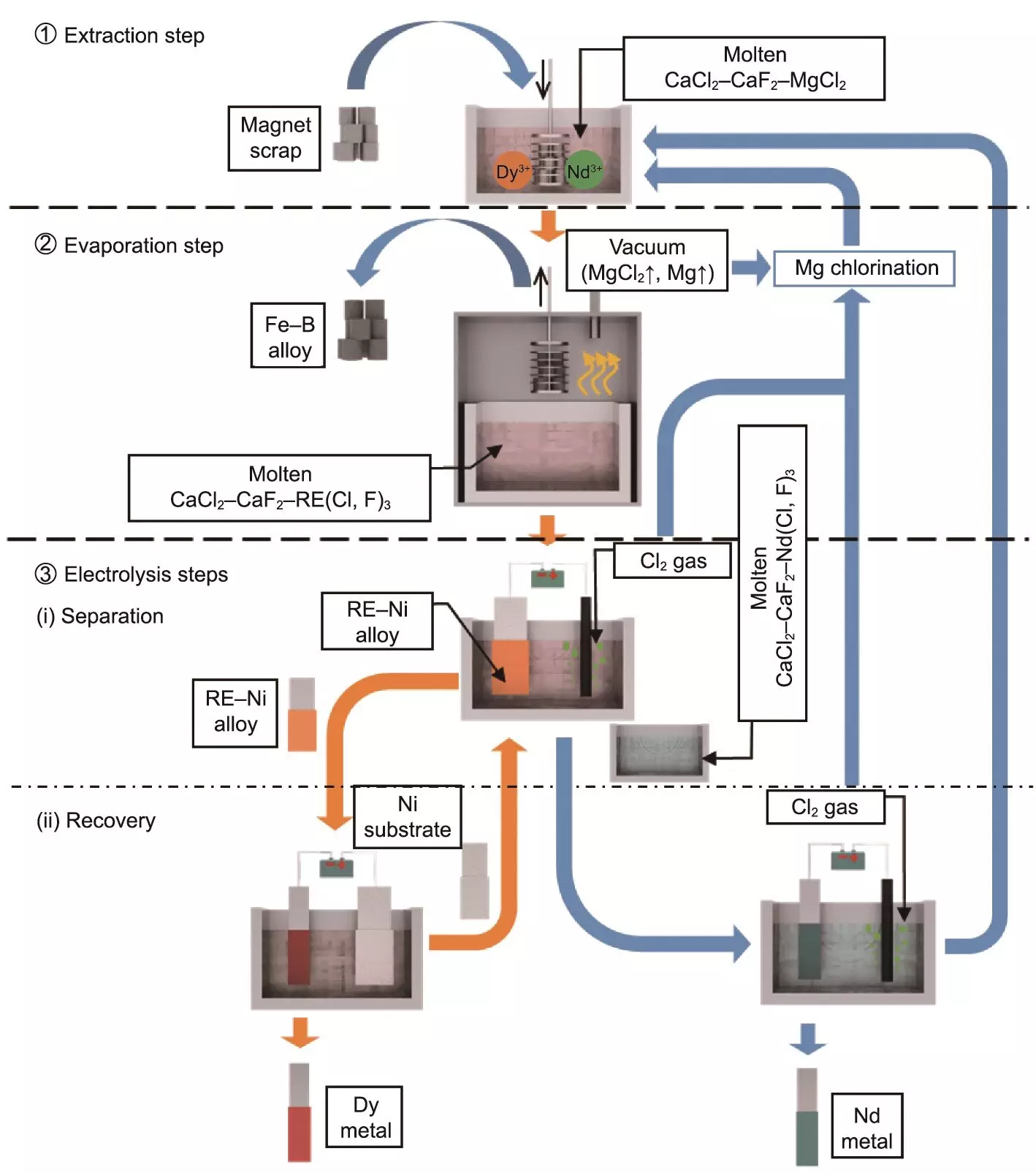

The SEEE process comprises three pivotal stages, each meticulously crafted to maximize efficiency and minimize environmental impact. The first stage, selective extraction, utilizes a molten salt mixture, which includes calcium chloride (CaCl2) and magnesium chloride (MgCl2). The addition of calcium fluoride (CaF2) ensures that evaporation losses are kept to a minimum, enhancing the overall extraction efficiency of REEs from magnet scraps.

The second stage focuses on selective evaporation, a critical step where excess extraction agents and byproducts are eliminated, resulting in a more concentrated form of REEs. This not only simplifies the subsequent processing but also safeguards the integrity of the extracted materials, which is essential for achieving high purity levels.

The final stage hinges on selective electrolysis, where the extracted REEs undergo electrochemical separation based on their unique formation potentials. This innovative stage is vital for producing high-purity metals of both Nd and Dy, achieving recovery rates as remarkable as 96% for Nd and 91% for Dy, both exceeding 90% purity. These exceptional results stand in stark contrast to traditional recycling methods, which are often cumbersome and environmentally taxing.

The implications of adopting the SEEE process are substantial. As the demand for electric vehicles and renewable energy sources increases, so does the urgency for sustainable recycling solutions. Traditional mining and extraction methods have detrimental environmental effects, including habitat destruction and significant carbon emissions. By integrating the SEEE method into recycling efforts, industries can reduce their reliance on virgin materials, thus alleviating the environmental costs associated with mining.

Moreover, the research team, led by professor Toshiyuki Nohira, suggests that the SEEE process has broader applications beyond Nd magnets. Its adaptability could extend to other areas such as the reprocessing of nuclear fuels, showcasing versatility that can impact a range of sectors. This not only enhances the economic viability of the process but could also be instrumental in meeting diverse resource recovery needs in various industries.

While the SEEE process demonstrates immense potential, researchers acknowledge that further technical evaluations are essential for its industrial-scale implementation. Challenges related to scaling the process, ensuring consistency in recovery rates, and addressing any unforeseen environmental impacts must be thoroughly investigated.

The study underscores the importance of advanced research in engineering solutions that align with global environmental objectives, particularly in the context of transitioning to carbon-neutral technologies. The findings advocate for continued innovation in the fields of recycling and materials recovery, emphasizing the integral role that advanced methods like SEEE can play in achieving sustainability.

As the world races to meet growing demands for green technologies, advancements such as the SEEE recycling process represent not only a scientific breakthrough but also a vital strategic shift. These innovative solutions are essential for overcoming the multifaceted challenges of resource scarcity, promoting environmental stewardship, and ensuring a sustainable future for succeeding generations.

Leave a Reply