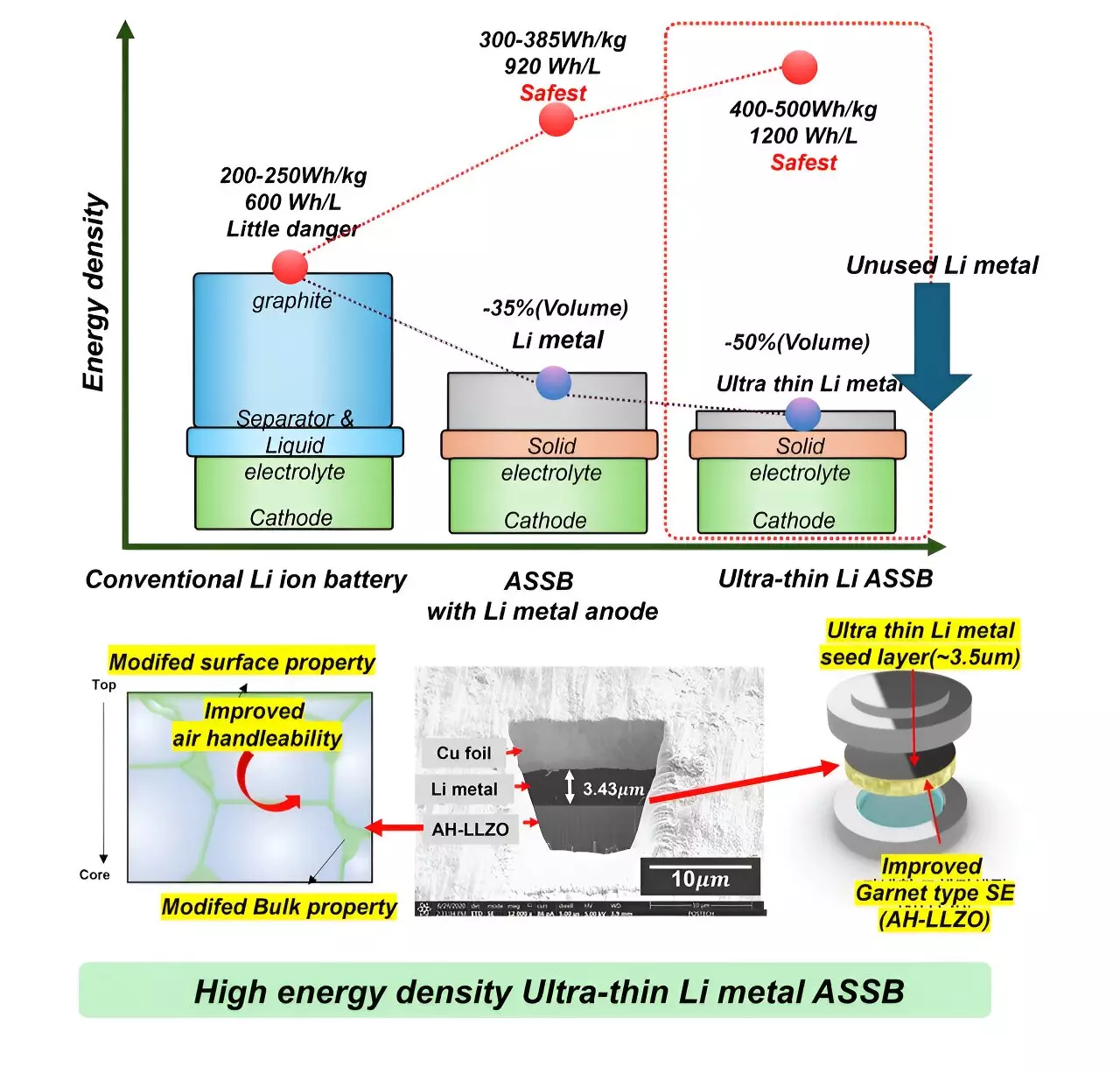

In the realm of battery technology, scientists and researchers are constantly striving to improve energy density and safety. One area of focus is solid-state batteries, which utilize solid electrolytes instead of liquids. These batteries, often referred to as “dream batteries,” are considered the next generation of energy storage solutions. One common hurdle in solid-state battery development is the formation of contaminant layers on the surface of the solid electrolyte, particularly when exposed to air. Traditional approaches to addressing this issue involve coating the electrolyte surface or implementing additional chemical treatments. However, these methods only offer partial solutions, as the contaminant layer tends to reform upon exposure to air once again.

A research team at Pohang University of Science and Technology (POSTECH) took a different approach to tackle the contaminant layer issue in solid-state batteries. Led by Professor Byoungwoo Kang and Dr. Abin Kim from the Department of Materials Science and Engineering at POSTECH, the team focused on enhancing the properties of the garnet-type oxide solid electrolyte (Li7La3Zr2O12, or LLZO) itself rather than relying on external coatings or treatments. By delving into the core essence of the problem, they developed an innovative technology known as air-handleable LLZO (AH-LLZO) that prevents the formation of contaminant layers altogether.

The key to the team’s success lies in the creation of a new hydrophobic compound (Li-Al-O) on both the surface and interior of the LLZO material. This compound effectively inhibits the formation of contaminant layers, even if they do form, by minimizing their reaction with moisture in the air. As a result, the contact and wettability with lithium metal is significantly improved, allowing for the development of ultra-thin lithium solid-state batteries. These batteries, with a thickness of approximately 3.43 micrometers, boast a capacity ratio of the anode to cathode of only 0.176. This not only reduces the amount of lithium metal required but also enhances energy density by decreasing overall battery weight and volume.

The implications of this research are vast in the realm of battery technology. The ability to prepare ultra-thin lithium metal layers using a simple wetting process, without the need for complex post-processing steps, marks a significant advancement in solid-state battery development. Additionally, the technology allows for the storage of batteries in air without requiring special handling or facilities, simplifying the manufacturing process and increasing the practical usability of garnet-type solid electrolytes. Professor Byoungwoo Kang aptly summarizes the impact of the research, stating, “We have solved the problem of LLZO’s inherent contaminant layer without the need for a post-processing step.”

The complexity of solid-state battery issues can often be simplified by focusing on the core “essence” of the problem. The innovative approach taken by the research team at POSTECH serves as a testament to the power of simplicity in finding solutions to complex challenges. As technology continues to advance, it is crucial to remember that sometimes, the answer lies in stripping away the complexities and getting back to basics.

Leave a Reply