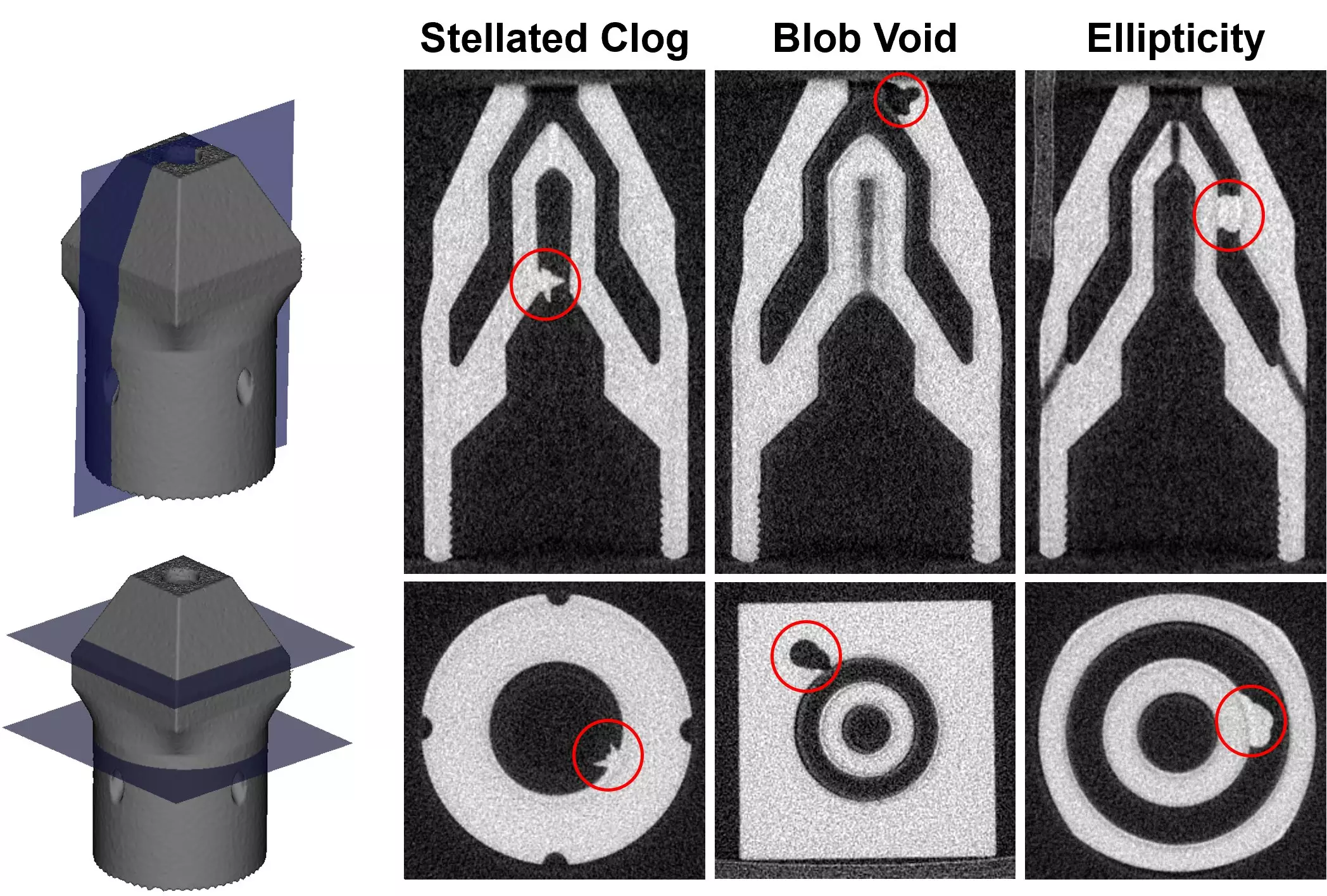

One of the key challenges in any manufacturing process is to ensure that the components produced are free of defects. This task becomes even more complex in additive manufacturing, also known as 3D printing, due to the intricate three-dimensional shapes and internal features of the components. These features are often difficult to observe and inspect using traditional methods.

Researchers at the University of Illinois Urbana-Champaign have come up with a groundbreaking solution to this problem by utilizing deep machine learning technology. By employing computer simulations to create thousands of synthetic defects with varying sizes, shapes, and locations, the researchers were able to train a deep learning model to accurately identify defects in additively manufactured components.

Testing and Validation

The algorithm developed by the researchers was put to the test on physical parts, some of which were known to be defective while others were defect-free. The results were remarkable, with the algorithm successfully detecting hundreds of defects in real physical parts that had not been previously recognized. This innovative technology has the potential to revolutionize the quality control process in additive manufacturing.

By using computer simulations and deep learning algorithms, researchers can quickly and effectively identify defects in additively manufactured components with high accuracy. This approach allows for the detection of defects that were previously unseen by traditional inspection methods. Deep learning, coupled with advanced imaging techniques like X-ray computed tomography, enables the inspection of internal features and hidden defects in 3D components.

The research conducted by the team at the University of Illinois Urbana-Champaign is a significant step forward in the field of additive manufacturing quality control. The integration of deep machine learning technology in defect detection processes has the potential to improve the reliability and efficiency of manufacturing operations. With further advancements in this area, the industry is poised to benefit from enhanced product quality and reduced production costs.

Leave a Reply