The collaboration between various prestigious research institutions and organizations has led to groundbreaking discoveries in the field of material science. By utilizing the unique environment of space, researchers have identified new opportunities for creating materials that are not readily available on Earth. Through experiments conducted on the International Space Station (ISS), scientists have successfully produced unconventional glasses in microgravity. This innovative approach has opened up a plethora of possibilities for developing advanced materials with enhanced properties.

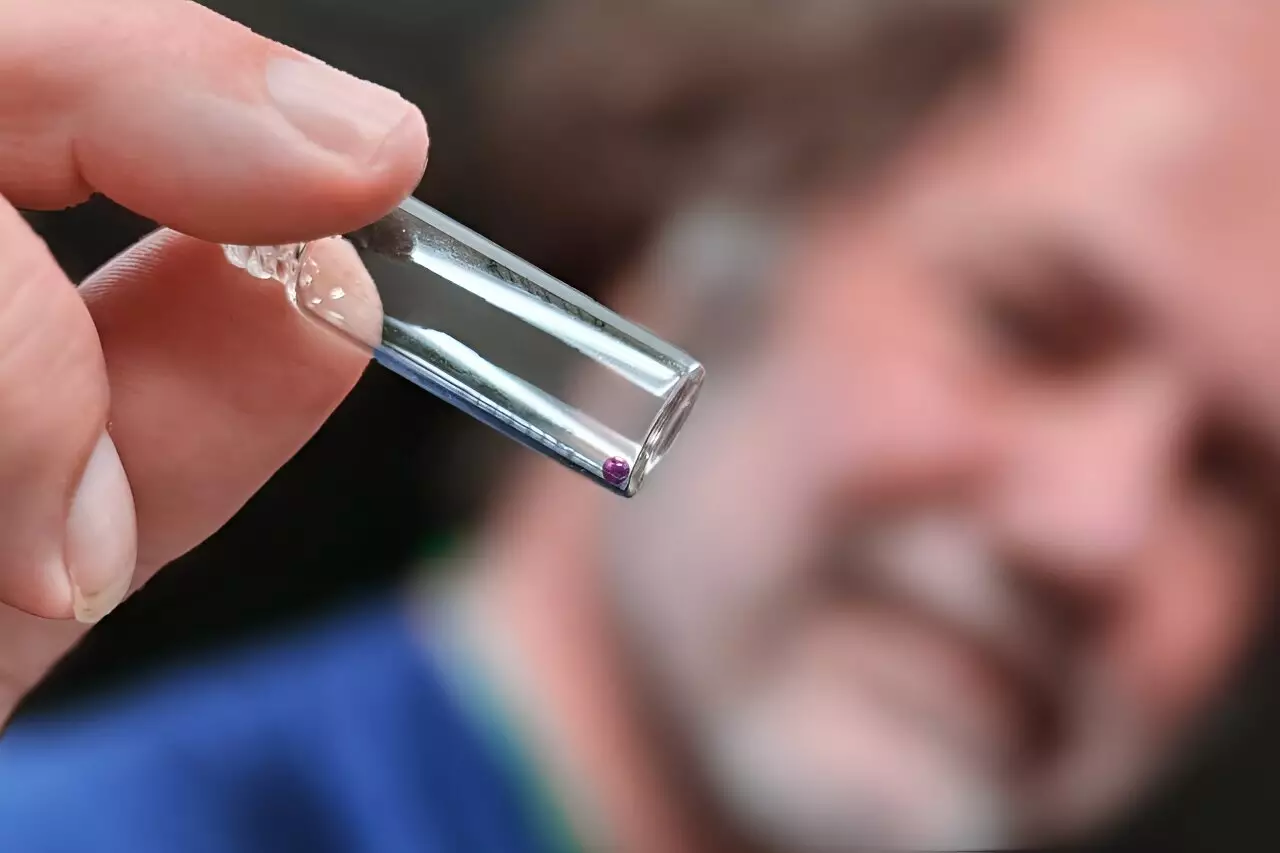

One of the key elements of the research involved the use of levitators to suspend material samples during experiments, avoiding interference from contact with other materials. This remote control method enabled operators on Earth to make and melt glass aboard the ISS, paving the way for the creation of unique glass beads in space. The researchers employed a combination of neutron, X-ray, and microscopic techniques to analyze the properties of the space-produced glass compared to its terrestrial counterpart. By studying the atomic structure and arrangement of atoms in the glass samples, the team was able to gain valuable insights into the potential applications of these materials.

Glass, unlike crystalline solids, exhibits a complex atomic arrangement characterized by a random network of molecules that share coordinate atoms. This unique structure, though stable, offers a wide range of possibilities for different forms of glass, including polymer, oxide, and metallic varieties. The research team’s experiments with oxides of neodymium and titanium have uncovered novel strengths and optical properties that have the potential for exciting applications in various industries. By exploring the structural nuances of glass at the atomic level, scientists can unlock new opportunities for developing cutting-edge optical materials and devices.

The combination of neutron and X-ray techniques has proven to be invaluable in analyzing the atomic structure of glass and other materials. Neutrons enable scientists to visualize lighter elements like oxygen, while X-rays provide insights into heavier elements such as neodymium and titanium. By conducting parallel analyses with both techniques, researchers can gain a comprehensive understanding of the arrangement of atoms within a sample. This multi-faceted approach allows for the detection of subtle differences in the composition and structure of materials, essential for advancing our knowledge of material science.

Future Implications of Space-Based Manufacturing

As researchers delve deeper into the realm of space-based manufacturing, the possibilities for developing innovative materials continue to expand. By leveraging the unique conditions of microgravity, scientists can explore uncharted territories in material science and engineering. The insights gained from experiments conducted in space provide a glimpse into the future of material development, offering opportunities for creating materials with unprecedented properties and applications. As we continue to push the boundaries of scientific exploration, the intersection of space and material science holds immense promise for driving technological advancements and innovations in various industries.

Leave a Reply